GEARS

By Jim McGinn & Kristoph Minchau

Terms

Force: How hard something pushes.

Torque: How hard something that is turning, pushes.

So a force tries to push something, and a torque tries to turn something.

Uses of Gears in Robotics

Motors have low torque and high speed. Usually we need high torque and low speed. Gears are used:

- To convert the motion from a fast electric motor that has low torque, to a slow motion with high torque (which is useful to push a robot).

- To transfer motion from one shaft to another while keeping the shafts sychronized.

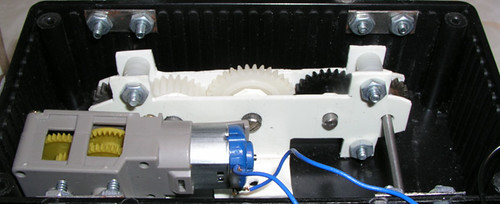

The white gear box above transfers the motion of the left shaft, to the right shaft, and keeps them synchronized. The motor/gearbox (in the lower left corner) is a Tamiya.

How Gear Work

If you turn the small gear, the big gear goes slower.

If you turn the big gear, the small gear goes faster.

The slow one has more torque (it can push harder). This is good for moving robots, arms, etc.

The fast one has less torque, but more speed. This is good for fans and anything where you need speed but not much torque.

By using a series of gears, called a "gear train," you can get speed reductions of 1 to several hundred (eg. 1:250).

Figuring Out The Gear Ratio

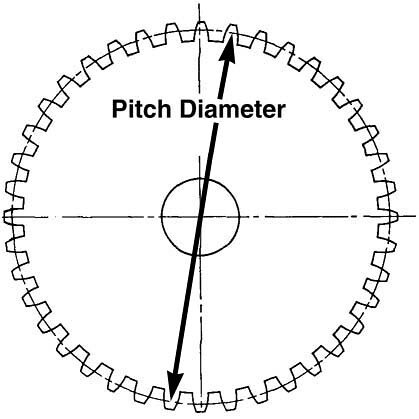

Gears work as if they were wheels rolling against each other, with the wheel diameter equal to the Pitch Circle Diameter. In other words, the "effective wheel diameter" of a gear is the Pitch Circle Diameter.

If you have two gears, the Speed of the slower (bigger) gear = the Diameter of the smaller gear / Diameter of the larger gear * the Speed of the smaller gear.

Choosing Gears

If you need to build a gearbox, you must use gears that "work together." This means they must have the same "diametral pitch" and "pressure angle."

Diametral Pitch

Diametral Pitch (or just "Pitch") P = Number of teeth / Pitch Diameter.

The Pitch Diameter Circle goes to approximately half way up the height of the teeth.

Common (diametral) pitches are 12 (big teeth), 24, 32, 48, 64 (fine teeth).

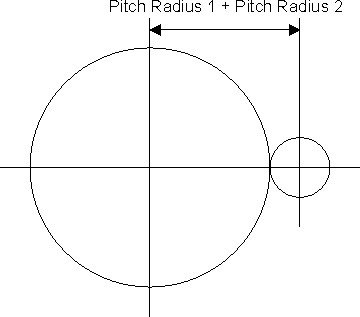

Knowing the pitch diameter is very useful. To figure out how far apart the shafts of two gears should be, add the pitch radius of the first gear with the pitch radius of the second gear.

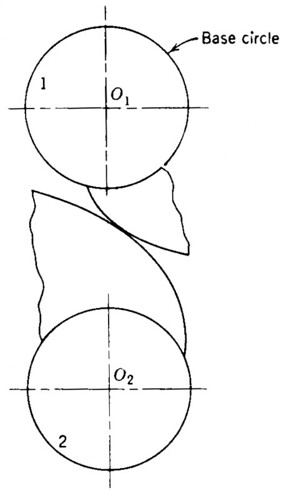

The teeth of the gears actually roll against each other- they do not slide:

Putting the gears the correct distance from each other (not too close or too far), minimizes the stress and maximizes the life of the gears.

TIP: How To Figure Out The Exact Pitch Diameter of a Gear (Imperial)

When scrouging IMPERIAL gears, estimate the pitch diameter, count the number of teeth, then divide the number of teeth by the pitch diameter to get the approximate (diametral) pitch.

Figure out what pitch the gear is by assuming it is one of these 12, 24, 32, 48, 64. (Note: If it is not close to one of these, it may be a metric gear or a non-standard gear.)

Then take the number of teeth, and divide it by the exact pitch, to get the exact pitch diameter.

If you can't determine the exact pitch diameter, estimate it, and make sure the mating gears are not jammed tight together. In the diagram under Backlash below, note that the top of the teeth do not touch the base of the teeth in the other gear.

Pressure Angle

When the teeth of two gears touch, the point where they touch is at a bit of an angle (from the radius). Both teeth must touch at the same angle for the gears to work as they were designed.

In practice, if you are building a small robot (like a mini-sumo) with plastic gears that you have scrounged, don't worry about this. If two gears don't have the same pressure angle, they will wear out faster, but for small robots that are not used that much, this probably will not be a problem.

If you are building a big robot, or if you are buying the gears, make sure they have the same pressure angle. 20 degrees is the most common, but some gears are 14.5 degrees.

Types of Gears

Spur gears are the "normal" gears. You can also get rack, worm, and bevel (not shown) gears, as well as other uncommon gears.

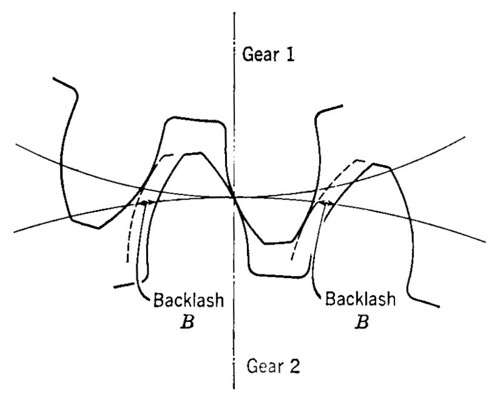

Backlash

When your motor switches direction, the gears have to move slightly before they contact the other teeth. This called "backlash." With a gear train with lots of gears, it is quite noticeable. This can be a problem in robotic arms.

Recommendations

It is easiest to use a "gear head" motor. This is a motor with a built-in gearbox (or it comes with a gearbox that you have to put on it, like the Tamiya motor/gearboxes). The Tamiya motor/gearboxes available from HVW Tech are a good place for many beginners to start.

If you need to build a gearbox, make sure the holes for the shafts are placed precisely (see Diametral Pitch above). Don't jam them together.

Lego gears work very nicely.

PM Hobbies usually has a limited selection of general purpose plastic gears. Old printers and VCR's have gears. Never throw these out without scrounging the gears. (Keep the springs, also.)

If you want to learn more about gears, the Lego Mindstorms set is great for experimenting. You can build lots of different gear arrangements with this. Also check the Internet for Lego gear ideas.

*Diagrams are from Mechanisms and Dynamics of Machinery, by H.H. Mabie and F.W. Ocvirk, 1978.